Wedge Wire Filter

Wedge Wire Filter

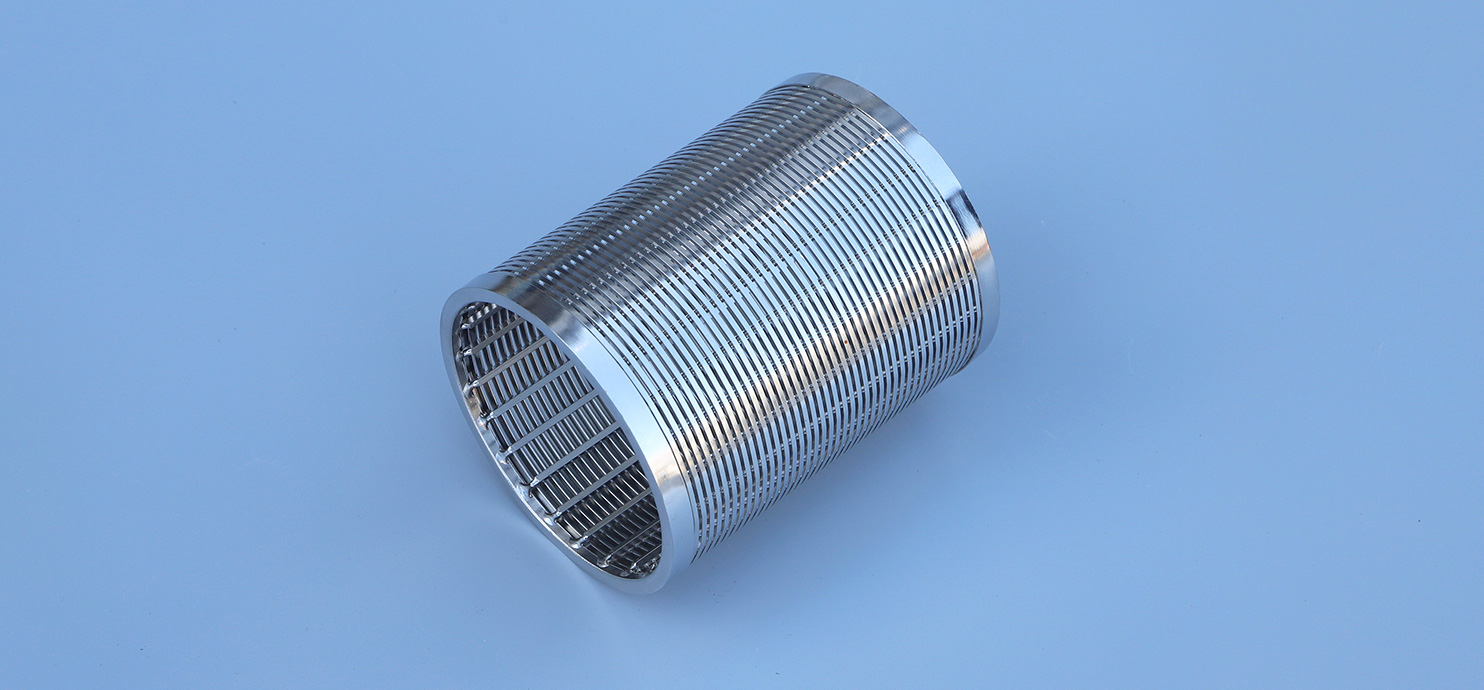

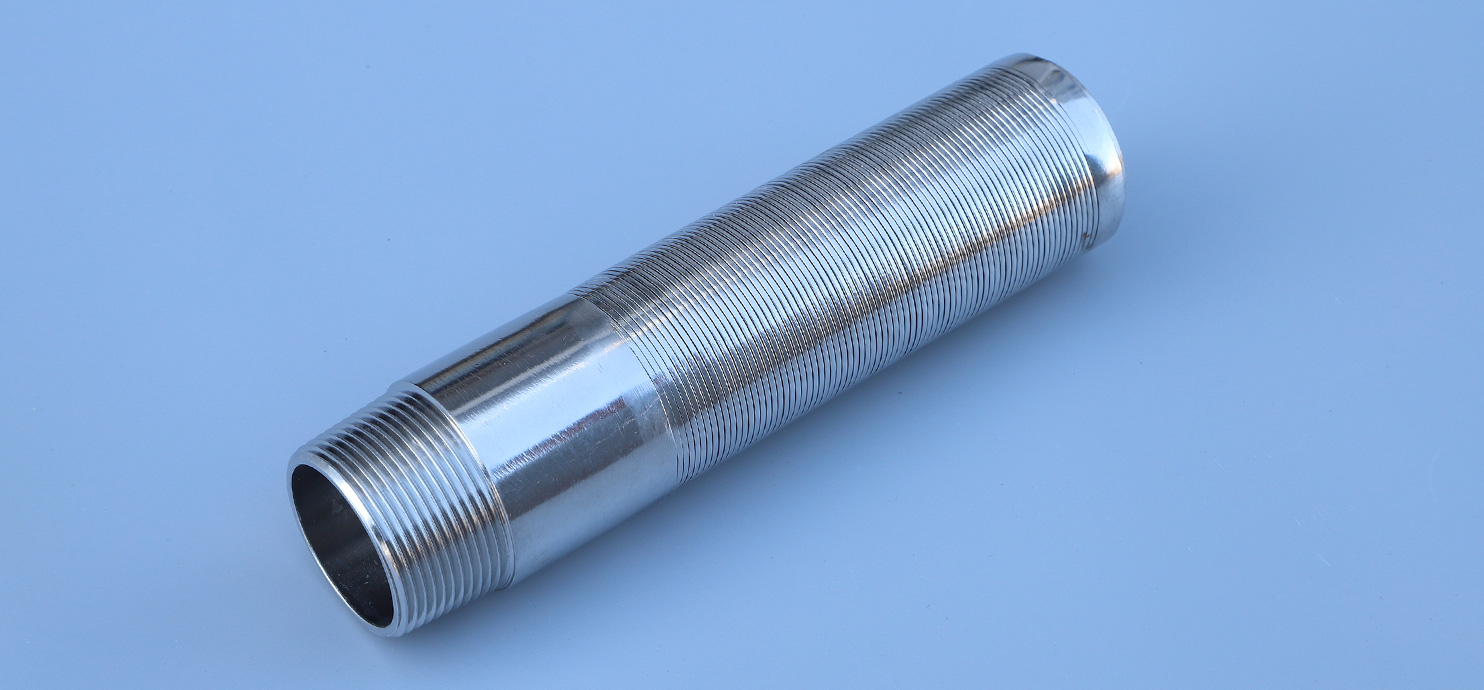

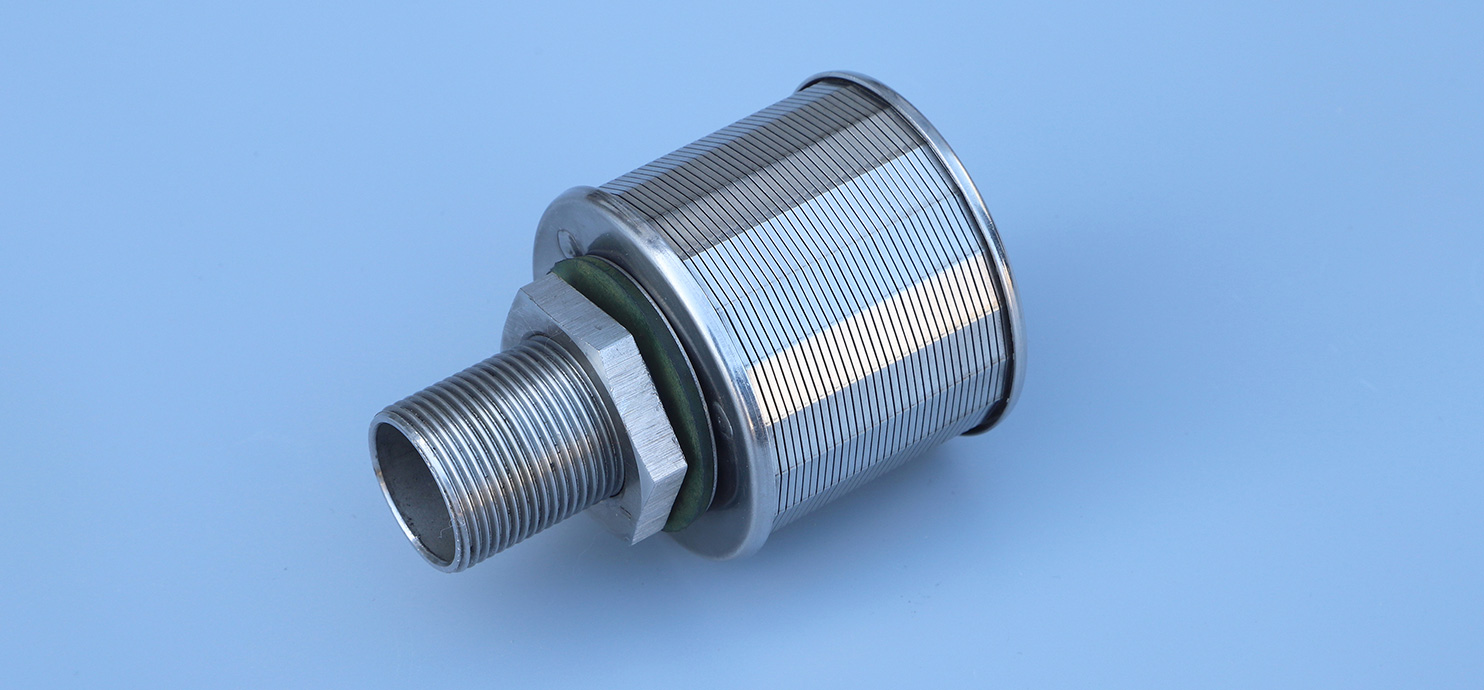

AHT/Hartong Wire Mesh Co., Ltd. wedge wire filter is also known as wedge wire strainer, wedge screen filter, wedge wire filter strainer, using high quality wedge wire as filter medium, welding, or stamping processing. Typically, wedge wire filters are designed with inward-expanding V-shaped slots to reduce solid particle clogging, designed to remove impurities and particles from liquids and gases, providing high-quality filtration and separation. As a wedge mesh filter element manufacturer, AHT/Hartong Wire Mesh Co., Ltd. adopts mature wedge wire filter processing, technology, durable, long-term use without deformation. We can provide a wide range of filtration support for the chemical, food and beverage, mining, environmental protection and other industries. If you are interested in further discussing the technical details of the wedge filter or cooperation opportunities, please feel free to contact us.

Display

Wedge Wire Filter Specifications

*Filtration rate: 15-800μm

*Diameter: 14-800mm

*Length: up to 6000mm

*Temperature: up to 815℃

*Other diameters and lengths are available upon request

Wedge Wire Filter Characteristics

Strong carrying capacity

Hartong wedge filter is designed with self-supporting function and cross-point welding, which not only has the characteristics of strong structure, high mechanical strength, strong bearing capacity and long service life, but also can reduce maintenance and replacement costs.

Strong tolerance

Hartong wedge wire filter has the characteristics of pressure reduction, wear resistance, corrosion resistance, uniform gap size and structural strength, long-term use can ensure stable performance.

High filtration accuracy

The filter efficiency of Hartong wedge wire filter can reach more than 90%, the filtration accuracy is as low as 15µm, and the working efficiency is high.

High degree of freedom

Hartong wedge wire filter mesh seam size can be freely adjusted, the structure is diverse, the filtration direction is flexible, easy to adjust.

Easy to clean

The surface structure of the Hartong wedge screen filter is smoother and easier to clean. When cleaning metal wedge wire filters, there is less risk of material damage than woven wire filters.

Wedge Wire Filter Production Capacity

AHT/Hartong Wire Mesh Co., Ltd. is a set of design, research and development, production as one of the metal filter manufacturer, covers an area of about 40,000 square meters, the annual output value of up to 2l$ million, has been engaged in the field of metal filtration for more than 20 years, has a complete production line and dozens of professional metal filter engineers, support different specifications of wedge wire filter customization. We will provide you with OEM services on a long-term basis to meet your specific filtration needs.

You can provide your application requirements and system parameters, and our professional engineers will give you a perfect solution.

Wedge Wire Filter Certificates

AHT/Hartong Wire Mesh Co., Ltd. has a strict quality control system and has owned and fully implemented the following relevant certification systems:

ISO9001 Quality Management System Certification

ISO45001 Occupational Health And Safety Management System Certification

ISO14001 Environmental Management System Certification

ATF16949 Automotive Industry Quality Management System Certification

Authorized Economic Operator

Wedge Wire Filter Packaging

Plastic film & Plywood case

Wedge Wire Filter Applications

The wedge wire filter element is widely used in various industries where efficient filtration and separation are required. Some of the common applications include:

Water Treatment

Wedge wire filter elements are commonly used in water treatment plants to remove impurities, sediment, and particles from water. They are used as pre-filters, primary filters, and final filters in different stages of the water treatment process.

Food and Beverage Industry

In the food and beverage industry, wedge wire filter elements are used to remove impurities and particles from liquids such as juice, wine, and beer. They are also used in the production of dairy products such as milk, cheese, and yogurt.

Petroleum and Chemical Industry

In the petroleum and chemical industry, wedge wire filter elements are used to filter various types of liquids and gases, such as crude oil, diesel fuel, and natural gas. They are also used in the production of chemicals and petrochemicals.

It provides high-quality filtration and separation, and is available in different sizes and configurations to meet specific application requirements.